|

|

|

Home »

Our Product » Lead Scrap

Lead Scrap

Like copper, lead has also been a familiar metal

used by human beings since ancient times. Lead, a highly malleable and easy

to melt metal, is widely used in various industries even today. However, due

to its highly toxic nature, the use of lead has been facing pressure from

environmentalists in recent years.

The pressure to end manufacture of lead-based paints is an example of the

growing concern on the potential health hazards caused by lead. Plastics,

aluminum, tin, and iron are replacing the use of lead in construction

materials, containers, packaging, etc. Tin and other metals are being used

to replace lead as a solder in some applications where lead could poison

people, such as in drinking water systems.

Lead is a very corrosion-resistant, dense, ductile, and malleable blue-gray

metal that has been used for at least 5,000 years. Early uses of lead

included building materials, pigments for glazing ceramics, and pipes for

transporting water. The castles and cathedrals of Europe contain

considerable quantities of lead in decorative fixtures, roofs, pipes, and

windows.

Prior to the early 1900's, uses of lead in the United States were primarily

for ammunition, brass, burial vault liners, ceramic glazes, leaded glass and

crystal, paints or other protective coatings, pewter, and water lines and

pipes.

The advent of the electrical age and communications, which were accelerated

by technological developments in World War I, resulted in the addition of

bearing metals, cable covering, caulking lead, solders, and type metal to

the list of lead uses. With the growth in production of public and private

motorized vehicles and the associated use of starting-lighting-ignition

(SLI) lead-acid storage batteries and terne metal for gas tanks after World

War I, demand for lead increased.

Most of these uses for lead continued to increase with the growth in

population and the national economy. Contributing to the increase in demand

for lead was the use of lead as radiation shielding in medical analysis and

video display equipment and as an additive in gasoline. By the mid-1980's, a

significant shift in lead end-use patterns had taken place. Much of this

shift was a result of the U.S. lead consumers compliance with environmental

regulations that significantly reduced or eliminated the use of lead in

nonbattery products, including gasoline, paints, solders, and water systems.

More recently, as the use of lead in non-battery products has continued to

decline, the demand for lead in SLI-type batteries has continued to grow. In

addition, the demand for lead in non-SLI battery applications also has

continued to grow. Lead is processed & refined from lead scrap

batteries. Non-SLI battery applications include motive sources of power for

industrial forklifts, airport ground equipment, mining equipment, and a

variety of nonroad utility vehicles, as well as stationary sources of power

in uninterruptible electric power systems for hospitals, computer and

telecommunications networks, and load-leveling equipment for electric

utility companies. By the early 2000's, the total demand for lead in all

types of lead-acid storage batteries represented 88% of apparent U.S. lead

consumption.

Other significant uses included ammunition (3%), oxides in glass and

ceramics (3%), casting metals (2%), and sheet lead (1%). The remainder was

consumed in solders, bearing metals, brass and bronze billets, covering for

cable, caulking lead, and extruded products. Lead is mined in the United

States, Canada, Mexico, Australia, and Peru. More than 1 million tons of

lead is recovered in recycling annually, the majority of which is from the

recycling of batteries. Australia and China are the leading suppliers of

lead in the world. China, India, Japan, US and European Union are the main

consumers of lead in the world. Lead is traded mostly as soft lead, animated

lead, lead alloys and copper-based lead scrap.

India imports nearly 50 percent of its lead requirement every year. Lead

production in India is estimated to be around 82,000 ton, mostly from

secondary sources. Lack of any major lead ore deposit is the main constraint

for enhancing domestic lead production. The domestic industry is

characterized by the presence of only a few players in the primary segment.

The primary lead industry in India is divided between the following main

players: Binani Industries Limited and Sterlite Industries (India) Ltd.

(Hndustan Zinc Ltd.). Due to increasing use of lead in domestic market both

players are expanding their smelting capacities for lead. Lead in the global

market is traded as soft lead, animated lead, lead alloys and copper-base

scrap.

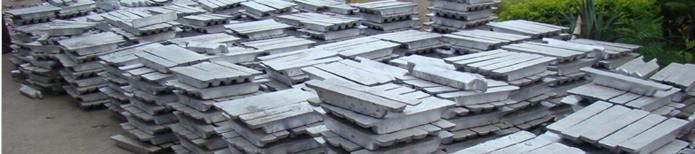

Pure Lead

Pure Lead Ingot is being produced from Raw Lead

Bullion / Remelted and Secondary Lead Ingots / Lead Scraps though

Pyro-metallurgical process. Refining Process, producing Pure Lead Ingots

with a minimum purity level of 99.97% by weight but achieves purity level of

99.985% in most of cases.

The typical composition of Refined Lead / Pure Lead:

|

| Elements |

Symbol |

Composition in % |

| Antimony |

Sb |

0.001 (max) |

| Arsenic |

As |

0.001 (max) |

| Tin |

Sn |

0.001 (max) |

| Copper |

Cu |

0.001 (max) |

| Bismuth |

Bi |

0.025 (max) |

| Iron |

Fe |

0.001 (max) |

| Nickel |

Ni |

0.001 (max) |

| Silver |

Ag |

0.003 (max) |

| Zinc |

Zn |

0.001 (max) |

| Calcium |

Ca |

0.0005 (max) |

| Sulphur |

S |

0.0005 (max) |

| Aluminum |

Al |

0.0005 (max) |

| Selenium |

Se |

0.0005 (max) |

| Cadmium |

Cd |

0.0005 (max) |

| Tellurium |

Te |

0.0010 (max) |

| Lead |

Pb |

99.970 (min) |

|

|

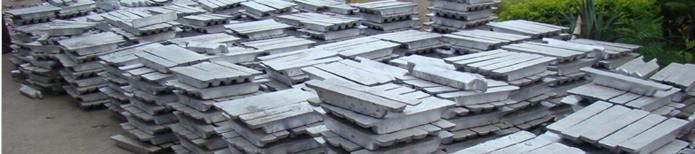

Lead Recycling

Production of Recycled Lead; Lead has the highest

rate of recycling of all metals. Because of its corrosion resistance, lead

scrap is available for recycling decades or even centuries after it is

produced. New environmental regulation in many countries has greatly reduced

the dissipative uses for lead such as paint, leaded gasoline, pigments,

stabilizers, solder, and ammunition.

At present time, just under half of the total world lead production of 7.62

million tons comes from recycling of scrap materials. Lead has the highest

rate of recycling of all metals. Because of its corrosion resistance, lead

scrap is available for recycling decades or even centuries after it is

produced. New environmental regulation in many countries has greatly reduced

the dissipative uses for lead such as paint, leaded gasoline, pigments,

stabilizers, solder, and ammunition.

At present time, just under half of the total world lead production of 4.7

million tons comes from recycling of scrap materials. There has been very

little change in recent years in the total amount of lead production or in

the percentage of recycled lead. Only in the past few years has the amount

of recycled lead increased. The rate of lead production from scrap materials

is expected to increase dramatically in the future.

Sources Of Lead Scrap

The major source of scrap lead for recycling in the

United States and throughout the world is lead acid batteries. Scrapped lead

acid batteries and the associated manufacturing plant scrap represent over

90% of the contained lead available for recycling. Used automobile batteries

represent about 85% of the lead acid battery scrap materials. Other lead

recycled scrap materials are sheaths from telephone and power cable, lead

pipe and sheet, weights (particularly automobile and truck wheel weights),

anodes, printing metals, dross's, residues, sludge's, and dusts.

In Europe and throughout most of the rest of the world, scrapped lead acid

batteries represent only about half of the lead scrap input to recycling

plants. Scrap cable covering, lead sheet and pipe, and miscellaneous metal

scrap items represent a much higher percentage of input scrap to recyclers

in these countries than those in the United States. As the number of

vehicles increases, the percentage of scrap represented by lead acid

batteries will increase.